L.A. Council visits BRI Energy

As part of a learning expedition for Greig Smith's R.E.N.E.W. LA Plan, members of the L.A. City Council journeyed to Fayetteville, Arkansas to examine a pilot plant demonstration of a revolutionary technology for the conversion of waste-to-ethanol. BRI's process utilizes bacteria to convert gasified syngas into ethanol.

Excerpt from the report are below. Pictures of the facility are contained in the actual report.

--------------------

BRI ENERGY, LLC And BIOENGINEERING RESOURCES, INC

GASIFICATION–FERMENTATION PILOT FACILITY (Arkansas)

Monday, November 21, 2005

Facility: BRI (Gasification-Fermentation) Pilot Plant.

Location/Site: The BRI pilot plant is located outside the City of Fayetteville, Arkansas, which is surrounded by farmland within a two-mile radius. The plant started operating the fermenter process unit in 1991 and the gasification unit in 2003. Each process unit is enclosed in separate buildings and the administration building houses the laboratory where further research continues to take place. The lot size is about 5 acres.

Feedstock: Wood, corn stover, tires, RDF (Refuse-Derived Fuel) and Material source-separated biodegradable waste (not municipal solids waste, MSW, although MSW has been successfully tested.)

Throughput: 1.5 tpd.

Conversion Technology: Thermal and Biological – Gasification-Fermentation.

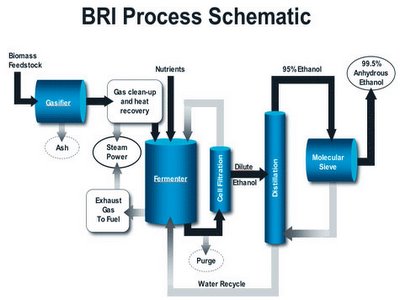

Process Description: The organics in the source-separated biodegradable waste are converted to syngas via BRI’s two-stage thermal gasifier that raises the syngas temperature to over 2000°F in the second stage to enable cracking of any heavy hydrocarbons to carbon monoxide (CO) and hydrogen (H2) maximizing the ethanol yield. There are hundreds of these units in operation, worldwide with a demonstrated reliability of 95 percent. The hot syngas is then cooled to 100°F, in the process generating steam, and it is introduced into the fermenter containing a specialized microbial population that converts the syngas into ethanol and H2O. Nutrients are added to provide the cell growth and automatic regeneration of the biocatalyst. The resulting dilute aqueous stream of ethanol is continuously removed through a membrane that retains cells for recycle to maximize reaction rates. Anhydrous ethanol is produced by conventional distillation followed by a molecular sieve, using the waste heat from the process. Water, with nutrients, is recycled from the distillation bottoms back to the fermenter. Air emission control systems remove almost all air pollutants.

The BRI pilot unit can process a maximum of 1.5 tons per day of various feedstocks, which include pre-sorted MSW (after removal of plastics, metals, and glass) and shredded to a size of 2 inches and 5 to 10 percent moisture content. The entire process claimed by BRI from gasification to distillation is approximately seven minutes. Due to its maximum process feed rate of 2 lb/min, the pilot unit must be fed manually.

2 comments:

Another benefit of the BRI process is that it is surprisingly undemanding technology. The bioreactor operates at atmospheric pressure and body temperature (around 100F or 40C), so failures are unlikely to be catastrophic.

Gasifiers scale down pretty easily, in fact during WWII Scandinavians mounted water heater-size gasifiers on trucks and buses to convert waste wood into "producer gas" that was burned in conventional IC engines.

The distillation process is practically identical to what moonshiners use to produce drinking ethanol -- more like high school chemistry than rocket science.

Lastly "molecular sieves" are an industrial commodity pellet to be bought by the barrel. The pellets are simply dropped in the 95% alcohol distilled product to absorb the residual water. Then they are recovered, heated to about 350F to evaporate off the water, and reused virtually indefinitely.

Scalability is very important for a variety of reasons. I like the idea that many types of companies and collaborations can be drawn into developing and funding unique solutions using flexible, modular technologies. Many more global communities can get involved in a decentralized response to the megalithic energy and environmental challenges we have today.

Post a Comment