U.S. D.O.E.: 5-year Plan for Biomass Conversion

The U.S. Department of Energy has embarked on a long-term, systematic program to convert biomass into fuels, chemicals, materials and power. Earlier this year the D.O.E. Biomass Program released their 2007-2012 plan for orchestrating the development of feedstock infrastructure, sugar research, thermochemical conversion, products development, and integrated biorefineries. The full document is a crystal ball of business opportunities for venture capitalists, utilities, municipalities, research institutions, and compatible businesses.

The U.S. Department of Energy has embarked on a long-term, systematic program to convert biomass into fuels, chemicals, materials and power. Earlier this year the D.O.E. Biomass Program released their 2007-2012 plan for orchestrating the development of feedstock infrastructure, sugar research, thermochemical conversion, products development, and integrated biorefineries. The full document is a crystal ball of business opportunities for venture capitalists, utilities, municipalities, research institutions, and compatible businesses.

What's missing is any reference to "urban" waste (unrecyclable municipal solid waste) as feedstock which is estimated to be 40 million tons per year in California alone and which, unlike other feedstock, is a mounting social liability in urgent need of diversion.

-------------------

U.S. Department of Energy: Energy Efficiency and Renewable Energy (EERE) Biomass Program

The U.S. Department of Energy (DOE) Biomass Program develops technology for conversion of biomass (plant-derived material) to valuable fuels, chemicals, materials and power, so as to reduce dependence on foreign oil and foster growth of biorefineries. Biomass is one of our most important energy resources. The largest U.S. renewable energy source every year since 2000, it also provides the only renewable alternative for liquid transportation fuel. Biomass use strengthens rural economies, decreases America's dependence on imported oil, avoids use of MTBE or other highly toxic fuel additives, reduces air and water pollution, and reduces greenhouse gas emissions. Today's biomass uses include ethanol, biodiesel, biomass power, and industrial process energy.

Tomorrow, biorefineries will use advanced technology such as hydrolysis of cellulosic biomass to sugars and lignin and thermochemical conversion of biomass to synthesis gas for fermentation and catalysis of these platform chemicals to produce slates of biopolymers and fuels. To expand the role of biomass in America's future, the DOE Office of the Biomass Program fosters biomass technologies with a balanced portfolio of research and development. While there are various other technologies for biomass conversion, the following graphic shows those that the Biomass Program is concentrating on, as outlined in its Multi-Year Program Plan.

Here are some excerpts from the plan:

-----------------------

U.S. D.O.E. Biomass Multi-Year Program Plan

2.1.1 Biomass Program Technology Elements

The Biomass Program is structured around five R&D technology elements. The first four elements focus on core research and development (R&D) that emphasizes enabling technology for biorefineries. The fifth element focuses on integrating these core technologies into specific commercial biorefinery scenarios, or pathways.

• Feedstock Interface Core R&D. Focused on developing new sustainable agricultural and feedstock infrastructure technologies and methods that will be required to supply lignocellulosic feedstocks to future large-scale biorefineries.

• Sugars Core R&D. Focused on fundamental and applied research and technology development for producing low-cost sugars from lignocellulosic biomass.

• Thermochemical Conversion Core R&D. Focused on developing cost-effective, efficient thermochemical technologies for producing intermediate products (e.g., syngas, pyrolysis oil) from lignocellulosic biomass and biomass-derived biorefinery residues.

• Products Core R&D. Focused on converting low-cost sugars and thermochemical platform intermediates into fuels, chemicals, and heat and power.

• Integrated Biorefineries. Focused on demonstrating and validating the integration of the technologies and systems developed in the four Core R&D platforms in commercial-scale biorefineries.

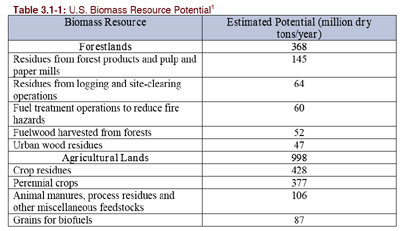

Biomass Resource Potential

This full resource potential could be available by mid-21st century when commercial-scale biorefineries are likely to exist. This annual potential is based on a more than seven-fold increase in production from the amount of biomass currently consumed for bioenergy and bio-based products. The existing feedstock supply infrastructure—harvesting, collecting, storing, preprocessing, and transporting—will need to be expanded significantly (>3.5 times today’s corn industry) to accommodate this large increase in biomass production.

The Feedstock Platform and Feedstock–Sugars Interface

The Feedstock Platform and Feedstock–Sugars Interface R&D focus on developing the new technology and methods necessary to produce and supply over one billion tons of biomass feedstock per year in a sustainable manner at $35/dry ton or less. This will require working closely with USDA, growers, feedstock equipment manufacturers, and processors to bring about the necessary changes in the agricultural and forestry systems and to form the integrated partnerships needed to supply fully-operational biorefineries.

Thermochemical Conversion

Thermochemical conversion provides an effective approach for producing fuels and products from a wide variety of biomass feedstocks, because it can readily convert all components of whole biomass, including lignin (a residue of fermentation process) and spent pulping liquors, to intermediate building blocks. Conversion of the lignin (typically 20%-30% of the biomass) to products is essential to achieve high efficiencies and added value in the biorefinery. Unlike the sugar fermentation processes, thermal processes are "omnivorous" in this regard and can convert all biomass feedstocks or residues to gas or liquid intermediates. In addition, in cases where there is low water availability, high lignin content, degradation during harvest, or diffusely distributed resource, which is a significant fraction of the available biomass resource; thermochemical conversion can provide a means to access the entire energy content of the 1.3 billion ton/year biomass resource.

technorati bioenergy, strategy, DOE, syngas, government, biofuels, feedstock, ethanol

No comments:

Post a Comment