One of my favorite chemical engineers is Robert Rapier who writes the ever entertaining R-Squared Energy Blog.

One of my favorite chemical engineers is Robert Rapier who writes the ever entertaining R-Squared Energy Blog.

He recently wrote an article entitled Cellulosic Ethanol Reality Check which is a critique on the hype surrounding "cellulosic ethanol" (CE). In the article he runs calculations on the volume of biomass necessary to support a CE plant and the farming acreage needed to supply that quantity. Although he is all for extending research for CE, he still feels it is being oversold by many investment-hungry entrepreneurs.

The bottom line is that it is going to take enormous swaths of land to supply these cellulosic ethanol plants, and it is questionable whether a farmed source of biomass can be counted on to run the facilities. Better to locate cellulosic ethanol facilities close to a massive source of waste biomass – say a very large municipal dump in which paper is sorted out, a paper mill, or some other consistent source of large volume biomass. If you then use the unconverted waste biomass for process heat, you could end up with a workable process.

I certainly don't advocate giving up on cellulosic ethanol, but we do need to approach this with a realistic and sober outlook. Men once desired to turn lead into gold. That was ultimately a futile quest (unless you want to try something like a nuclear reaction), but with cellulosic ethanol there is much more at stake. My impression is that many people in our government are basing energy policy decisions on the presumption that cellulosic ethanol is a done deal. My advice would be to have several backup plans.

Below is my extended response...

--------------------

Cellulosic Ethanol – Snake Oil for the new millennium?I am a big believer that RD&D in cellulosic ethanol will reap big rewards for society. But while enzymatic hydrolysis may help squeeze out some return from agricultural waste, I am not confident that it justifies the full frontal RD&D that the D.O.E. seems to be endorsing.

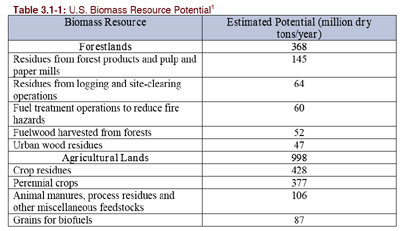

The best feedstock for cellulosic ethanol is waste, which can be converted into biofuels using gasification and syngas fermentation. We are not talking about growing anything here or using any extra acreage. We are talking about converting agricultural, industrial, forest, and urban blight into cleaner air, cleaner lands, and cleaner fuels. In short, we are talking about extending recycling on a mass scale.

In L.A. we (the utilities including the LA/Department of Public Works and the LA Co. Department of Sanitation) are working on diverting landfill garbage to biorefineries - not just because of the electricity and biofuels we can generate but because we have a "Peak Landfill" problem. It's a much cleaner solution than waste-to-rail - shipping unrecyclables on 3-mile long trains each day 200 miles to the desert.

I just wrote an article about the

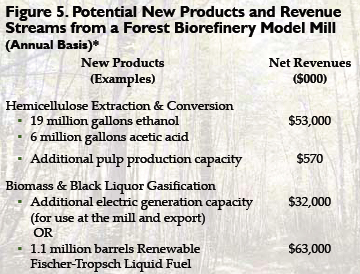

forestry products industry call for using similar biorefineries to convert paper and pulp mill waste into electricity and biofuels using gasification. No extra trees needed - just blight to reprocess and fire-prone, diseased trees to convert. And the industry recognizes that the time is ripe because all their combustion boilers are hitting the end of their lifecycles.

We need to have a new industrial revolution focused on replacing combustion with gasification so that we can control carbon emissions. Syngas fermentation will help sequester the carbon in biofuels, green chemicals, and other new products.

I believe that the solution to the biofuels issue, and renewable energy in general, is going to be very gradual and decentralized.

Ethanol will not solve every problem. But it is a near universal fuel extender for internal combustion engines - and gradual infrastructural change is what we need right now (unless we are prepared for nuclear reactors and all-electric cars).

Ag is great for producing energy feedstock but it requires alot of input energy in the form of fertilizer, harvesting, and transport. Ag, forestry, and urban waste "harvests" are much more predictable, much more decentralized, and requires no excess cultivation.

I wish people would look more closely at waste as a cheap feedstock (some even say it is negative cost feedstock). It is the existing residual to our very wasteful industrial and waste management infrastructures. Not even the

D.O.E. looks at it seriously enough and it is a WIN-WIN-WIN solution resource. Even if the net energy was zero, at least we would mitigate the waste disposal problem.

Carting wood to centralized biorefineries is not the low hanging fruit of biomass conversion. Instead, pulp and paper mills will very probably replace their boilers with gasification units and process their existing pre- and post-processing waste on site. This will extend their existing practice of producing much of their own energy while providing them with additional income opportunity. See

Renaissance of the Forest Products Industry.

Same with municipal solid waste (MSW). Biorefineries will process the waste at the sorting centers where, at least in the L.A. plan, there is plenty of extra facilities space. This will save 2/3 of the diesel used to send the residual to landfills - and save 3/4 of the need for the landfill. See

Expanded Recycling.

Since gasification allows for blended feedstock, new decentralized biorefineries will have great flexibility to respond to resource changes. For instance, wood-based or bagasse-based biorefineries in the Southeast could, in my scenario, respond to Katrina-type catastrophes by processing the excess C&D waste of the destruction. This would save the region the multiple blights of the destruction while creating jobs, reducing disease, and resupplying some of the lost energy.

It may sound like "snake oil" - but it's the best liquid fuel alternative we've yet to fully explore.

technorati

wood,

feedstock,

conversion,

biofuels,

biorefineries,

forests,

biorefineries,

forests,

waste

December 2006 saw major developments in the commitment of whole industries to a new paradigm shift to renewable energy.

December 2006 saw major developments in the commitment of whole industries to a new paradigm shift to renewable energy.