There is a battle raging in the halls of Sacramento over the future of waste disposal in California. In many ways identification of the true guardians of waste disposal environmentalism is being brought into question.

The crux of the debate concerns overdue changes in state regulations defining "conversion technologies" (CTs) and their place in the current waste hierarchy. The outcome of the struggle will determine whether the environmental movement to recycle the state's growing waste problem will stall or move forward. At stake are a myriad of growing public concerns - not only waste disposal but also landfill availability, global warming, gas prices, ground pollution, air pollution, electricity generation, ethanol production, environmental justice, employment, and war-related oil dependency.

On one side are "old guard" idealists of established recycling and emissions watchdog organizations and their non-scientific supporters who have built the recycling infrastructure that exists today. As much progress as has been achieved to date, recycling has only managed to handle the growth of trash in the state and has failed to divert the original volume it was set up to reduce.

On the other side are "new guard" professional environmentalists from the scientific community, universities, government boards, utilities, and industry who have been actively involved in identifying, developing, and testing new CTs. These renewable bioenergy alternatives will significantly extend the amount of waste biomass that can be recycled.

Regrettably, the idealists have become the obstructive establishment that needs to open their eyes to new CTs (like gasification and pyrolysis) and the clearcut evidence of the innovation’s problem-solving potential and emissions-free performance. In their arguments, they insist that CTs conform to standards much more stringent than those established by the Air Quality Management District. When the positive test results are provided, the data is not challenged - it is ignored - frustrating the communication process.

As Ed Begley, Jr. wrote in November, 2005 in a letter to Assemblymember Loni Hancock of the Assembly Natural Resources Committee:

I recognize and applaud my colleagues in the environmental arena for the benefits their efforts and work over these many decades of Earth Days have accomplished. Perhaps the lack of a defining difference between pyrolytic conversion and incineration has clouded the ability of the non-scientific community’s mind to understand the difference.

Please consider comparing the environmental performance of conversion technologies against other methods of recycling, such as smelting plants that are not subject to the same repressive statutory and regulatory restrictions. In addition, consider the economic impact on California’s labor force of exporting recycled materials to China, when they could be put to better use here at home.

In March 2006, a Director of the Bioenergy Producers Association, Paul Relis, wrote an enlightening article for BioCycle magazine tracing the history of recycling and its potential for the future. Mr. Relis has been a chief negotiator in support of CT legislation in Sacramento (AB1090 and AB2118).

Below is the entirety of the article he wrote...

-----------------

Conversion Technologies, Recycling and Renewable Energy subscriber onlyby Paul Relis

BioCycle, Vol. 47, No. 3

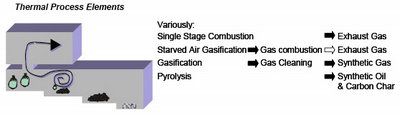

With the state's recycling rate at over 50 percent but landfilled waste still high, California debates best ways to convert organic residuals into sustainable power - and get support of environmental opponents.Paul Relis is founding Executive Director of the Community Environmental Council of Santa Barbara, California, and is now President of its Board of Directors. From 1991-1998, he was the Environmental Member of the California Integrated Waste Management Board. In 1998, he became Senior Vice President of CR&R, Inc. - a company which operates transfer stations and MRFs, and is building a green waste composting facility. He has visited conversion facilities worldwide.THERE is a vigorous debate underway in California over whether or not to encourage the development of conversion technologies (CTs). Conversion technologies refer to systems that can thermochemically (high temperature) or biochemically (low temperature) convert solid wastes now being landfilled into energy, liquid fuels such as ethanol, or chemicals.

The debate has pitted proponents of conversion technologies, mostly very small companies who have spent decades trying to apply specific technologies such as gasification, pyrolysis, and distillation to the management of the solid waste stream against California's major environmental and recycling organizations. Why should there be such a raging debate over CTs in California that has among the most ambitious recycling laws in the nation and progressive renewable energy policy? And why is this debate important to the future of waste and materials management in the U.S.?

The roots of the California debate go back to the mid-1980s when recycling was the long unfulfilled dream of environmentalists and recycling organizations. They were pitted against the incinerator firms, financial institutions and several large local governments such as Los Angeles, San Diego and Contra Costa Counties where proposals were under consideration to build large waste-to-energy facilities that required at least several thousand tons per day of dedicated waste. The facility opponents believed that if these projects were approved, they would doom recycling and foul California's already dirty air.

By the late 1980s, incineration proposals had politically been defeated. The elimination of waste incineration as a disposal option, coupled with a projected landfill crisis in Southern California, caused the California Assembly and Senate to embrace recycling. With the support of California's governor, the nation's most ambitious recycling bill (AB 939) was signed into law in 1989.

This far reaching statute set in motion a multibillion dollar investment in a recycling collection infrastructure - undoubtedly the largest investment by any state in the country. As a result of this investment, California's near 90 percent dependency on landfill in 1990 was reduced by nearly 40 percent by 2005. According to the most recent information from the California Integrated Waste Management Board, the state's diversion rate from landfill is at 50 percent.

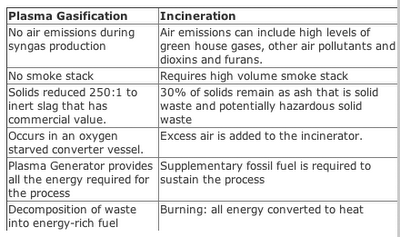

While AB 939 extensively promoted recycling, it was also explicitly an antiincineration bill. For the handful of incinerators that existed at the time of its passage, it limited diversion credit for these facilities and discouraged any future development of incineration. It also lumped any technologies even remotely related to incineration, such as pyrolysis and gasification, into the same category as incineration along with distillation. Consequently, for the next 15 years little, if any development of these technologies were undertaken in California.

FACTORS CONVERGE

By 2003, a convergence of factors were beginning to manifest in California that gave rise to taking another look at so called “noncombustion” thermochemical technologies such as gasification. Spiraling energy prices in California spurned on by the Enron debacle and poorly conceived deregulation of the utility industry vastly increased California's expenditures for electricity. By 2004, concerns about global warming along with the reemergence of concerns over landfill capacity, particularly in Southern California, prompted a fresh look at what role CTs might play in California's integrated waste management system.

Responding to these and other considerations, the California Integrated Waste Management Board (CIWMB) was directed by the California legislature to undertake an extensive study of CT and to report back to the legislature on the status of these technologies, their public health impacts and their compatibility or conflict with recycling. The University of California was given a prime contract to evaluate the technical, economic and health impacts of conversion technology while RTI, a private consulting firm, was assigned the task of evaluating what impacts CTs might have on the recycling collection infrastructure.

SEVEN REGIONAL CONVERSION TECHNOLOGY FACILITIES

While these studies were underway, several local governments within the state undertook their own investigations of CTs by soliciting requests for qualifications from conversion technology vendors and subjecting these requests to third party evaluations. Los Angeles commissioned its own independent studies to determine if CTs might help meet its solid waste management needs. In total, more than $3 million have been spent on studies over the past two years to probe CTs' commercial viability, their environmental risks and benefits, and their relationship to continued development of recycling in California.

The Los Angeles study,

Evaluation of Alternative Solid Waste Processing Technologies, conducted by URS Corporation, found that with respect to air emissions both thermochemical and biochemical systems are “expected to result in emissions well below regulatory limits.” With respect to life cycle analysis, the study concluded that thermochemical and biochemical conversion technologies could be expected to “create significant energy savings when compared to landfilling. This energy savings results from a combination of syngas and electrical energy production, as well as from materials recovery and recycling.”

According to a recent resource management blueprint for Los Angeles,

RENEW L.A., the City of Los Angeles, in spite of its 62 percent diversion rate, still generates 14,000 tons of landfilled waste - enough waste to produce 100-340 megawatts of renewable energy a day or enough electrical power for 100,000 to 300,000 households.

The plan calls for the development of seven regional CT facilities over the next 20 years and argues that these facilities will have the following benefits for the City of Los Angeles:

• Drastic reductions in truck and rail transportation of waste and their associated air quality and traffic congestion impacts;

• Conservation of limited virgin resources;

• Significant reduction in environmental impacts from landfill;

• and Generation of renewable energy.

CONVERSION TECHNOLOGIES COMPLEMENT RECYCLING INFRASTRUCTURE

The findings in the

comprehensive study of CTs by the Riverside and Davis campuses of the University of California (UC) are consistent with the L.A. study with respect to environmental benefits, health concerns and renewable energy. In addition, the UC and RTI studies suggest that conversion technologies should complement, rather than conflict with, California's AB 939 recycling infrastructure. This is because most conversion facilities proposed in the state include either front end MRFs to further extract recyclables or extract recyclables within the conversion process itself. Estimates of further extraction of recyclables range from about five to 15 percent and these recyclables would come from the processing of garbage that is not currently being addressed by existing recycling programs. In cities and counties where recycling rates are already at 50 percent or greater, overall recycling rates with conversion technology could range from between the mid-50 percent range to as high as 70 percent.

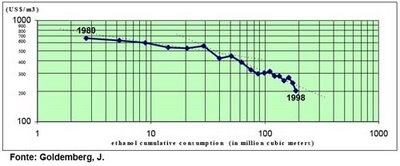

The UC study found that “CTs provide the potential of converting materials that are currently landfilled into electricity, chemical, or other products such as synthetic diesel and gasoline transportation fuels.” As much as 10 percent of California's electrical demand could be met through the development of CTs. CTs could meet much of California's ethanol demand using currently disposed MSW.

The UC study states that: “Existing data and facilities in locations around the world indicated that conversion technologies can operate within constraints established by regulatory requirements…These factors indicated that it is very likely that conversion technologies with the most advanced environmental controls would be able to meet regulatory requirements in California.”

These findings were based upon extensive information on CTs gathered from around the world, particularly in Europe and Japan where the most conversion facilities exist that have used municipal wastes as a fuel source. Actual emission levels from operating facilities were obtained from government regulators in these countries rather than reliance upon industry sponsored data. In addition, several pilot facilities in the United States provided their data to the UC. Researchers from the UC were allowed to witness the actual emissions testing and review the results.

The UC study concluded that conversion technologies can meet California's regulatory requirements with respect to specific emissions concerns such as dioxins and furans, and that test results suggest that emissions would be many times below the regulatory requirements of the Federal Republic of Germany, Japan, the U.S. EPA and California's South Coast Air Quality Management District.

DEBATE CONTINUES ABOUT MOVING FORWARD

Proponents of CT point to Europe's massive commitment to curbing greenhouse emissions as a rationale for CT development in the U.S. On a personal note, I was in Berlin last winter and visited several thermochemical and biochemical systems in neighboring Brandenburg and Saxony. I met with German officials from the State of Brandenburg and the German Green Party to discuss attitudes towards conversion technologies with respect to global warming, compatibility with recycling and their ability to meet Germany's tough air and other emissions standards. In Germany, and indeed throughout the European Union, global warming is taken much more seriously than in the U.S. Since landfills are a large source of greenhouse gas emissions, the German officials I talked to expressed the position that any system that removes more material from landfill such as recycling, composting and CTs is greatly preferable to continued reliance on landfill.

However, even with these positive findings, many environmental and recycling organizations remain opposed to conversion technology and some are fighting tooth and nail to defeat any proposed facilities. Why is this so? Why would organizations identified with protecting the environment fall on the sword, so to speak, to prevent their use given the comprehensive environmental benefits that the independent studies suggest will ensue from the use of CTs? Answers to these questions from an objective standpoint remain perplexing.

Conditions have changed markedly in California since the state enacted AB 939. Unlike 15 years ago, there are thousands of collection programs for recyclables; hundreds of processing facilities now exist, and they are considered by the state and most local governments to be sacrosanct. At the same time, the state population has grown by nearly more than seven million people and there has been no reduction in per capital waste generation. Disposal remains at nearly 40 million tons, and there is little prospect that recycling programs will grow to significantly impact this figure over the next decade. Meanwhile California faces acute energy shortages in the form of electricity, and it has virtually no in-state sources of ethanol to meet its liquid fuel requirements. Landfills remain one of the largest sources of greenhouse emissions in a state that has an expressed public policy to reduce greenhouse emissions. CTs offer among the few viable means of responding to these critical environmental needs.

In spite of the impartial studies by the state's most esteemed research university, in spite of actual emission test results using post-MRF municipal solid waste (MSW) from California, in spite of the evidence that CTs can contribute significantly to the reduction of greenhouse gases and improve air quality by reducing the transportation of solid waste throughout the state, opposition to CTs by the state's environmental and recycling organizations remains intractable.

At the time of this writing, legislation is being considered that would make conditions for the development of conversion technologies feasible. Negotiations are in progress to try to move this legislation to move forward. Whether these negotiations will prove successful or not, remains to be seen. The outcome will have important implications for the State of California. And to the degree that California is a trend setting state, to the rest of the nation.

technorati

biofuels,

conversion,

CTs,

greenhouse,

California,

legislation,

ethanol,

bioenergy