Advancements in "BioConversion"

Is it unreasonable to expect that the next major advancements in fermentation will come from the use of biological agents (enzymes, micro-organisms, and bacteria) to perform the metamorphosis of cellulosic feedstock into biofuels? Will nanotechnology play a role?

The ever enlightening Biopact blog has two recent articles on bioconversion advancements that are noteworthy in this regard.

----------------

Interview about 'third generation' biofuels

'First generation' biofuels consist of unmodified sugar, starch or oil crops being used to make ethanol or biodiesel, by utilizing the easily fermentable parts of the crop (in the case of ethanol) or by transesterifying seed oil. 'Second generation' biofuels rely on advanced bioconversion techniques, such as the enzymatic breakdown of ligno-cellulose to make ethanol. That way, much more biomass is available as a feedstock.

In 'third generation' biofuels, the energy crops or the bioconversion agents (bacteria, micro-organisms) themselves have been bio-engineered in such a way that the bioconversion process becomes more efficient. For woody crops for example, the lignin structure may be altered so that it breaks down 'on command' and releases the sugars needed, much easier.

In its "Young Innovator" series, the MIT Technology Review has an interesting interview with Michael Raab, a 33 year old bioengineer who is working on such 'third generation' biofuels.

Michael Raab is putting enzymes into corn that will make it easier and cheaper to convert the entire plant--kernels, husk, stalk, and leaves--into ethanol. These proteins allow processors to break the complex carbohydrates that make up most of the corn plant into simple sugars that can be easily fermented into ethanol.

Read more here...

---------------- Micro-biorefineries: nanotechnology and bioenergy meet

Micro-biorefineries: nanotechnology and bioenergy meet

...But there is another vision, one in which decentralisation, independence, localisation, '(re-)territorialisation' and dynamic, bottom-up decision making processes are the key concepts. Local communities become owners of their own energy infrastructure, resources and politics. It is within this paradigm that a consortium of British universities, supported by the University of Newcastle's spin-off Intensified Technologies Inc (ITI), is working towards the development of 'micro-biorefineries' that use locally produced biomass feedstocks and turn them into fuels, electricity, heat, and green specialty chemicals at a local scale, and fine-tuned to the ever changing needs of a particular community. The fascinating project combines nanotechnology with biotechnology to get there and promises to bring a highly dynamic, multi-purpose micro-factory to our neighborhoods.

The idea is to integrate different bioconversion processes, and to scale them down radically ('Process Intensification and Miniaturisation'). Three conversion steps are integrated, each using the residues of the precedent step:

• a first conversion and pretreatment of the base biomass through bacterial breakdown into a 'bio-sludge' with a high energy density

• conversion of the biomass residues that result from this process into ethanol through fermentation

• gasification of the residues that remain from this fermentation process into a synthesis gas, which has to be purified

Prison cells for bacteria

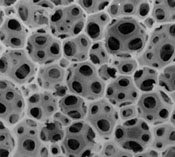

Key to the integration of the steps is the control of the behavior of bacteria, which play a role both in the breakdown and pretreatment of the initial biomass, as well as in the fermentation and purification steps. In order to control bacteria in a way that does not rely on manipulating their genetic properties, the consortium is developing porous nano-structures designed on a molecular scale. A new production process based on micro-waves allows the porous materials to be made in a matter of seconds, whereas a few years ago this took days. These structures are either made from polymer, metal or ceramic materials and form a kind of 'prison with cells' for the bacteria.

Read more here...

technorati bioenergy, bioconversion, biofuels, decentralization, renewable, investment, ethanol, nanotechnology

No comments:

Post a Comment