CA AB 1090 - 11/16/05 - Results of Independent Study of Emissions

A principal obstacle to the passage of AB 1090 has been the lack of emissions data for conversion technologies. To address this issue, the Center for Environmental Research and Technology of the Bourns College of Engineering of the University of California/Riverside (aka, CE-CERT) undertook emissions tests of three facilities:

1. International Environmental Solutions (IES) plant located in Romoland, California, a pyrolysis facility followed by thermal oxidation for the purpose of power generation

2. BRI Energy's pilot plant in Fayetteville, Arkansas, a gasification facility followed by synthesis gas fermentation of ethanol with cogeneration of electricity,

3. Integrated Environmental Technologies (IET) located in Richland, Washington, a plasma arc gasification facility whose design is primarily for the disposal of hazardous or medical wastes.

All three facilities' emissions tests indicate compliance or near compliance with the air pollutant emissions regulations of several standards. Only IES registered over compliance in any of the tests, but this result could be remedied with the installation of readily available technology prior to future emissions.

-----------------

Evaluation of Environmental Impacts of Alternative Thermal Conversion Technologies Using Municipal Solid Waste Feedstocks

William A. Welch

Principal Development Engineer

Center for Environmental Research and Technology

Bourns College of Engineering

University of California - Riverside

I have been involved over the past few years in alternative conversion technologies for energy production and/or waste reduction.

Today, I am going to speak to my experiences specifically with evaluation of several pilot plant operations in the United States, their emissions test results and where they stand in comparison to existing regulatory limits.

I am specifically going to speak to the International Environmental Solutions plant located in Romoland, California, a pyrolysis facility followed by thermal oxidation for the purpose of power generation, which was tested this summer with an MSW residual feedstock by an independent third party laboratory under a South Coast Air Quality Management District research permit.

The second facility is BRI Energy, which has a pilot plant in Fayetteville, Arkansas. It is a hybrid technology, a combination of thermal and biological conversion technologies. It has an up front gasifier which is a thermal technology followed by a bioreactor containing enzymes that convert the gasifier products into ethanol, with secondary heat that is used for electrical energy production.

The third technology is Integrated Environmental Technologies located in Richland, Washington, a plasma arc gasification facility whose design is primarily for the disposal of hazardous or medical wastes.

I have obtained test results from each of these facilities, and in the case of the first two actually observed the testing first hand and have done my own independent evaluation of those test results.

For comparisons to emission limits, I have looked at similar types of facilities, in particular the US EPA emission limits for starved-air combusters, which are used commonly in MSW incineration; the South Coast Air Quality Management District permit limits for the two incinerators we have here in the South Coast Air basin; and then, German limits. In Europe, they do have limits for gasification facilities using MSW.

The dioxin/furan emissions for all of three facilities (as shown above) were below existing US EPA limits for starved air combusters and German limits for thermal MSW conversion. I’ve not listed the South Coast limits for dioxins and furans because that is performed on a case-by-case basis.

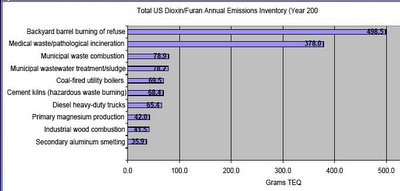

The current U.S. inventory of dioxin and furan emissions to the air (see chart on previous page) shows that the backyard burning of trash is still the largest source of dioxin emissions to the air in the United States at almost 500 grams per year. Medical waste incineration still poses a big concern as far as emissions of dioxins. Municipal waste combustion is the third highest level.

You can go down through more common industrial processes—the coal-fired boilers, cement kilns that use hazardous waste as a fuel supplement, heavy duty diesel trucks, primary magnesium production, industrial wood combustion…and I found it interesting that also on the list is secondary aluminum smelting. Aluminum recycling is also a significant source of dioxin and furan emissions, not subject, however, to waste board oversight.

All of these generated dioxin and furan emissions significantly above the levels of the tested conversion technologies, whose results represented raw data without standard emissions controls.

The pilot plant test results that we have witnessed and have evaluated independently indicate compliance or near compliance with air pollutant emissions regulations. Continuous and periodic monitoring of these processed is recommended. Care must be taken that these facilities are operated properly and monitored such that there is no accidental release of any component into the atmosphere. Further characterization of the solid and liquid residues is recommended. There is a potential for post-process recycling. Those materials that could not be removed up-front for some reason, such as glass and metals, depending upon the feedstock, could potentially be recovered in the char and ash.

——————————

CONTEXT: On November 16, 2005 the California Assembly Natural Resources Committee, Chaired by Hon. Loni Hancock, held a hearing in the Los Angeles City Council Chambers. A distinguished panel of speakers presented a series of arguments advocating the passage of AB 1090 - which would correct language in its predecessor (CA Bill AB 939 in 1989) and provide additional "diversion credits" for waste that is diverted from landfill. This hearing was full of facts from credible sources that are germaine to any debate on the subject of conversion technology - the need, the opportunity, the comparative emissions data, and the overall environmental benefits.

No comments:

Post a Comment