Plasma Gasification and Incineration Compared

One of the common objections to the use of gasification to effect waste-to-energy conversions is the irrational claim that "gasification is just another name for incineration." This is an old, false distortion of fact relating to controversy surrounding the use of waste-to-energy incinerators and the "Keep America Beautiful" program of the 1980's. As related by Ratical.Org:

One of the common objections to the use of gasification to effect waste-to-energy conversions is the irrational claim that "gasification is just another name for incineration." This is an old, false distortion of fact relating to controversy surrounding the use of waste-to-energy incinerators and the "Keep America Beautiful" program of the 1980's. As related by Ratical.Org:

In 1980 DOE projected that by 1987 there would be 160,000 tons-per-day of incineration capacity in the U.S. and double this by 1992. But in reality in 1988 incineration capacity was only 50,000 tons per day, and it was expanding at a snail's pace. In 1985 there were 42 new incinerators ordered, but by 1987 it was down to 25 and by 1989 new orders has dropped to 10. In 1987, for the first time in recent memory, more capacity was canceled (35,656 tons per day) than was ordered (20,585 tons per day). The incineration industry had hit a wall.

That wall was made up of local grass-roots citizens concerned about many aspects of solid waste incineration: dollar cost, hazardous air pollution, toxic ash, destruction of material resources, waste of energy, the political corruption that accompanies multi-billion-dollar public works projects, and the gobbling up of small, local waste haulers by the incineration giants.

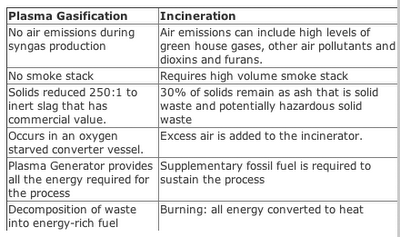

Gasification is NOT incineration as the side-by-side comparison of plasma gasification and incineration below demonstrates (as published on the website of the Plasco Energy Group). While this company is focused on the production of syngas, other companies (BRI Energy, Fuel Frontiers, and others) are focused on the fermentation of cooled syngas into biofuels (like ethanol).

-------------------

In plasma gasification the waste input is pyrolysed by the high temperature into its constituent elements: H2, O2, C, N2 etc. The converter conditions are controlled so that prior to exit, the elements reform into the desired syngas that is rich in CO and H2. The materials that can not be converted into syngas, such as metal, glass, rock and concrete are vitrified to produce an inert slag. The slag is 1/250th of the volume of the processed solid waste.

In incineration, excess O2 is added to the input waste so that at low temperature it burns. The result is heat and an exhaust of CO2, H2O and other products of combustion or partial combustion. As much as 30% of the processed solid waste remains as ash. This ash is a solid waste and could be categorized as hazardous solid waste.

technorati bioenergy, gasification, pyrolysis, conversion, biofuels, syngas, incineration,, plasma

5 comments:

Very good post! Thanks for opening my eyes to the differences!

Do you know of any good sites that describe and or give details on large (>5MW)PG facilities that are operational and commercially viable around the world

Good question. I assume you mean gasifiers that use municipal solid waste or biomass for feedstock as opposed to fossil fuels or systems that throw in a small percentage of biomass.

There was an Infocast conference in Denver last week that focused on fossil fuel gasification - "The Business of Power and Polygen" (http://www.infocastinc.com/index.php/conference/gasification ). If you don't know, polygen refers to growing interest within industry with the many things that can be generated in addition to power - steam, syngas, chemicals, fertilizers, etc. You might want to look at their conference brochure to see who is leading development.

I have talked to the Infocast organizers about putting on a conference devoted to biomass gasification. I own a list of about 100 projects throughout the world that are working in this field. I only have statistics on about a third of them for what their power output is and of those none are above 2Mw - but that may not mean that >5Mw aren't deployed within this list. Thermoselect is a pioneering developer.

There are wood-to-power plants that generate 50Mw using Circulating Fluidized Bed (CFB) boilers with low emissions. See the two articles I wrote about the deployment of the new Northern Wood Power Project in New Hampshire ( http://biostock.blogspot.com/search?q=PSNH ).

Gasifiers are much more expensive than CFBs but the controlled output of syngas is a reason to pursue gasifiers - particularly for polygen applications. Presumably, their cost will come way down through mass deployment - if we ever get there!

Scott

Had you looked at three plasma developments in the UK

1) Advanced Plasma Power using Gasplasma (combining CFB with plasma gasification)

2) Enviroparks in S. Wales with plasma gasification partner Europlasma.

3)Waste2Tricity in London with 2 year plans to use plasma gasification converting municipal solid waste to hydrogen for fuel cells

I am not aware of these developments, thanks.

What are the feedstocks for 1) and 2) and what are producing with the heat, syngas, and residues?

Post a Comment